1. INTRODUCTION

When the motor is rotating, the torque and rpm are varying as the loads or the driving status connecting through reduction units are changing. On the contrary, one can monitor changes of the loads or the driving status in the manner of measuring motor torque and rpm. Applications for torque and rpm measurements include determining the amount of power an engine, motor, turbine, or other rotating device generates or consumes. In the industrial world, ISO 9000 and other quality control specifications are now requiring companies to measure torque during manufacturing, especially when fasteners are applied.

Sensors make the required torque and rpm measurements automatically on screw and assembly machines, and can be added to hand tools. In both cases, the collected data can be accumulated on data loggers for quality control and reporting purposes.

Other industrial applications of torque sensors include measuring metal removal rates in machine tools; the calibration of torque tools and sensors; measuring peel forces, friction, and bottle cap torque; testing springs; and making bio-dynamic measurements.

There is a torque measuring method using the strain gauge and bridge circuit. A strain gage can be installed directly on a shaft. Because the shaft is rotating, the torque sensor can be connected to its power source and signal conditioning electronics via a slip ring. The strain gage also can be connected via a transformer, eliminating the need for high maintenance slip rings. Strain gages used for torque measurements include foil, diffused semiconductor, and thin film types. These can be attached directly to the shaft by soldering or adhesives.

But, because this is a contact method, it has the life time which is dependent on rotating velocity and used time. So this system demands on replacement of some parts or whole system itself for maintenance. And this system is also relatively big and expensive, requiring preceding annoying process.

The measuring method in rpm measurement can be divided into 3 main groups; mechanical, optical and stroboscopic measuring methods.

The mechanical method is the contact method and has the some disadvantage, but this method is still frequently used for low revolutions between 20 and 20,000 rpm.

The optical rpm measurement is the most popular and has the measuring range of 0 to 100, 000rpm. The rotation is transmitted to the measuring instrument via infrared light beam coming from the instrument which is then reflected by a reflective tape on the object.

The stroboscopic measuring method uses the stroboscopic principle and has clear advantages over other measuring methods using mechanical or optical sensors. Using this method, it is possible to measure the rpm of very small objects or in inaccessible places. It has the measuring range of 100 to 20, 000rpm.

In this paper, we are going to propose another non-contact method to measure torque and rpm using the Hall effects sensor. We have made reduction motor using planetary gear trains and put the Hall effects sensor in it. This motor unit also has the monitoring system that can measure the motor torque and rpm through the Hall effects sensors. This monitoring system includes the function of wireless communication with a remote server using Bluetooth protocol. It gives a motor unit to have the remote access point.

2. TORQUE AND RPM MEASURMENT

2.1 The special feature about planetary gear train

Most motor has a reduction unit on its center shaft to increase torque or to decrease velocity that can not be realized in a motor alone. In many applications, one gets desired torque and velocity using various gearboxes with adjusting reduction ratio.

There are many kinds of gearboxes, but the role of planetary gear trains is becoming more and more important nowadays. The method proposed by this study is the case with planetary gearboxes.

The obvious advantages of the planetary gear trains are the higher torque capacity, smaller size, lower weight and improved efficiency characteristics of a planetary design. The small size and modular construction of planetary gear trains also means that they can be assembled in several stages, providing high reduction capability from a highly compact package. As such, planetary gear trains are the preferred solution in many areas such as wheel and winch drives and also slewing drives for turning large diameter cogged items that require slow movement at very high loads.

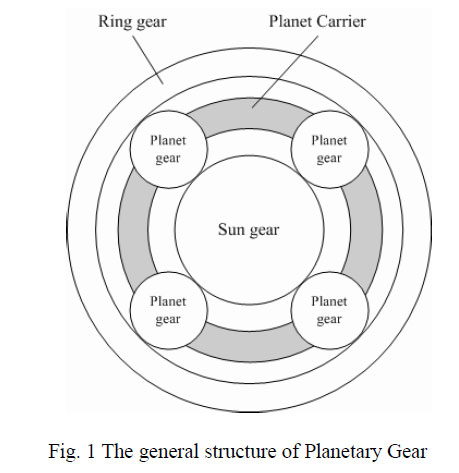

Fig.1 shows the general structure of planetary gear train. The special feature about planetary gear train is that they can produce different gear ratios depending on which gear you use as the input, which gear you use as the output, and which one you hold still.

In the method proposed by this study, we consider the case that the input is the sun gear, and we hold the ring gear stationary and attach the output shaft to the planet carrier. Of course, it is possible to apply our method to other cases: sun gear stationary or planet carrier stationary.

2.2 The basic idea for measuring Torque

In the gear train, the ring gear is fixed to the housing by an elastic material.

When the motor is rotating, the loads make some strain between the stationary element (the ring gear) and the rotating elements (the sun gear and planet carrier) by the action-reaction force. This strain pushes out the elastic material and then it makes some displacement corresponding to its torque.

Compare with ordinary method measuring the strain itself, we try to detect the displacement caused by the strain and the structural characteristic of the planetary gear train. We can measure this displacement by using the hall sensor and magnet pair.

2.3 The basic idea for measuring Torque

| Material | BH* | Temp. Stability (Tc in %/ºC) | Cost |

| Alnico | 5 to 10 | Excellent thru +150ºC(-0.02) | Moderate |

| Ceramic | 2 to 4 | Moderate thru +150ºC(-0.2) | Low |

| Flexible | 0.6 to 1.5 | Typ. Limitation of 100ºC(-0.2) | Lowest |

| Neodymium | 30 to 40 | Typ. Limitation of 125ºC(-0.12) | High |

| Samarium | 20 to 30 | Excellent thru +150ºC(-0.04) | Highest |

BH* is the product of flux density and field strength. In general, this value represents the energy density of the magnet and is used to grade permanent magnets. The higher the value is, the stronger the magnet is.

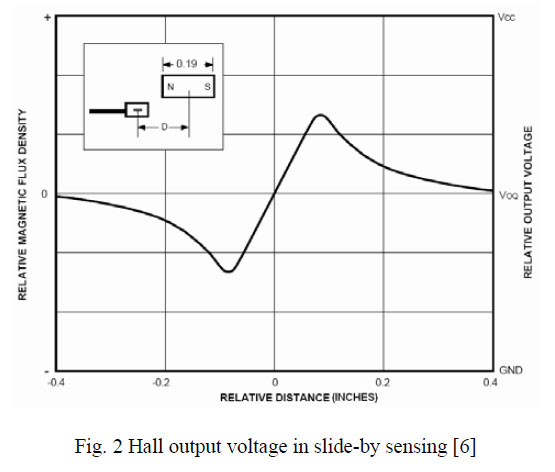

In many applications, the linear hall-effect sensors are used in conjunction with a permanent magnet. There are some methods to combine the magnet with hall-effect sensor. Fig.2 shows slide-by sensing method using single magnet that is a non-complex method of obtaining a linear output voltage vs. slide-by movement.

As shown in Fig.2, depending upon the location of the sensor relative to the zero-field center of the magnet, both negative and positive outputs can be produced and the center portion of the output is very linear. For our Hall sensor, the sensor output voltage at the center of magnet is Vcc/2.

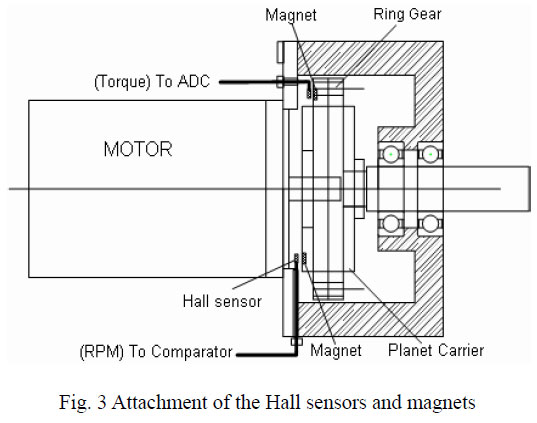

As shown in Fig.3, a proper magnet in the size and the magnetic force can be mounted directly on the ring gear. We make a hole on the ring gear supporter (elastic material) and simply attach the Hall sensor.

The air gap between the sensor and the magnet is another important factor for good sensitivity.

In general terms, the weakest magnets (flexible) would typically operate in a 0.25 mm to 2 mm range, while the strongest (neodymium or samarium cobalt) could allow an air gap of 4 mm to 6 mm.

The hall-effect sensor output voltage becomes the ADC input through the amplifier of the monitoring system.

The relations between the displacement and the torque also vary with the motor size, capacitance and types etc. So we should derive the relational equation or LUT (Look Up Table) measuring the each mechanical displacement from the various reference dummy torque. We consider LUT for compensating nonlinear characteristic of hall-effect sensor and other unknown factor.

2.4. Measurement of the RPM

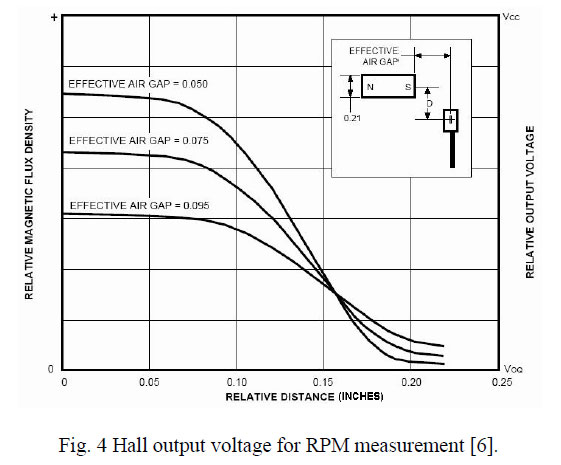

As shown in Fig.3, we have attached a proper magnet on the Planet Carrier and set the other hall-effect sensor on the opposite side of the magnet. As the motor is rotating, the magnet attached on the planet carrier is also rotating and it is passing by on the fixed hall sensor every rotation. Output hall voltage of this hall-effect sensor becomes the comparator input of the monitoring system. Fig. 4 shows another slide-by sensing method for measuring RPM.

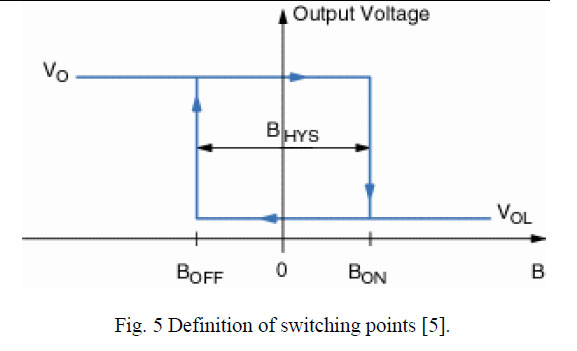

Comparing with Fig. 2, the hall sensor in Fig. 4 is sliding on the South Pole of the magnet. If the comparator input value exceeds the reference value, a counting flag will be set; on dropping below the reference value, a counting flag will be cleared. We can calculate the RPM with the time interval of this counting flag's period. We can also replace the Hall effects sensor with Hall Effect switch or Hall IC. Hall switches have an integrated comparator with predefined switching points and a digital output which can be adapted to different logic systems. All Hall switches include an open-drain output transistor and require an external pull-up resistor to the supply voltage. A standard Hall switch has a single Hall plate and responds to the absolute value of the magnetic field perpendicular to the plate. The Hall switch is characterized by the magnetic switching points BON (or BOP) and BOFF (or BRPN). If the magnetic flux exceeds BON, the output transistor is switched on. On dropping below BOFF, the transistor is switched off. The magnetic hysteresis BHYS is the difference between the switching points BON and BOFF. Fig. 5 shows this definition.

3. TORQUE SENSOR UNIT

On our experiments, we have developed the torque sensor module that consists of Hall sensor and magnet pair. The basic idea of our torque sensor takes from the photoelectric sensor that consists of emitters and receivers pair.

3.1 Torque Sensor Module by slide-by sensing

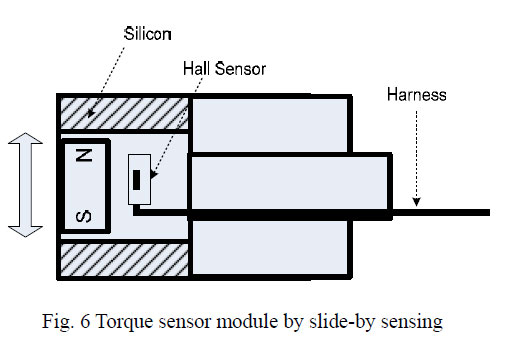

We have made first torque sensor module of Fig 6 and Fig 7 by slide-by sensing using the characteristic of Fig 2.

The magnet part which is covered with silicon is inserted to ring gear of Fig 3 and the other part is fixed at outer housing of the geared motor. When the motor is rotating, the flexible part has some displacements corresponding to additive torque as the ring gear moves back and forth.

3.2 Torque Sensor Unit by push-pull approach

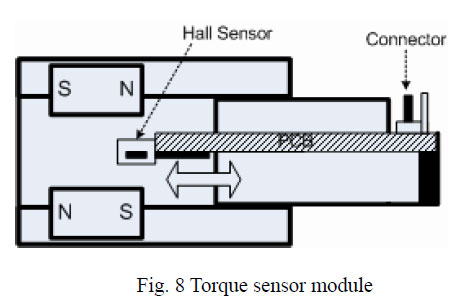

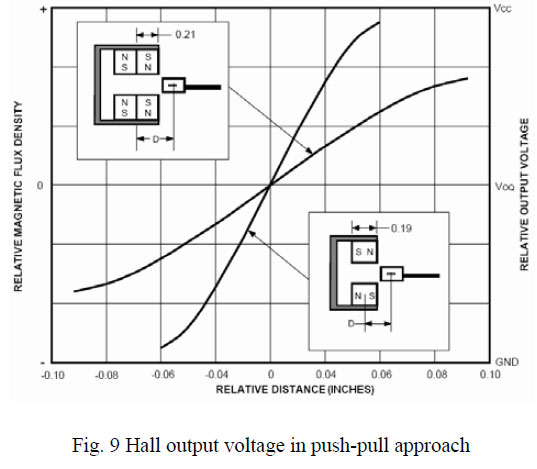

We can also make the housing itself using silicon and measure the displacement outside of the geared motor unit. In this case, the silicon outer surface itself has some displacements forced by ring gear as a motor is rotating. Therefore we have made second torque sensor unit which is operated in Push-Pull approach. Fig. 8 shows the structure of our torque sensor and Fig. 9 shows the characteristic of Hall output voltage in Push-Pull approach.

In the case of the Push-Pull approach, the torque sensor moves between two magnets. Complementary fields provide a linear, steep-sloped output. The output is nearly rail-to-rail (GND to Vcc) with polarity dependent upon magnet orientation. In our experiments, the displacement by torque is about 0.25mm at 29.4 N-m.

4. COMPUTING TORQUE, RPM AND POWER

4.1 Output Torque

The measuring torque is the calibrated output data from ADC using relational equation or LUT and the output torque is the final displaying value determined by following equation from the measuring torque.

T0 = T3 (z1 + z3 ) / z3 (1)

T0 : Output torque to display

T3 : Measuring torque

z1 : Number of teeth of the sun gear

z3 : Number of teeth of the ring gear

4.2. Measuring RPM (ω0) to display

As counting output pulse of the hall-effect sensor or hall-effect switch, we can easily calculate the rpm of the motor.

Differently hall-effect sensor, hall-effect switch has benefit that can be connected directly on the micro-controller input port without additional circuit like comparator, because their output hall voltages are discrete pulse. But because the Hall switch is characterized by the magnetic switching points BON and BOFF, we can not vary the reference value or the switching points.

The measuring RPM ω0 can be representative as following equation.

w0 = 60 × cntRotate (2)

cntRotate : Revolution per every second

Infrared sensor with reflective tape is another good choice for measuring rpm, but the size of planetary gearbox and infrared sensor itself must be considered.

4.3. Transmit Power (W)

The transmit power often becomes more useful and important measure than any other displaying values and can be calculated by multiplying the output torque and RPM.

W= T0w0 (3)

6. CONCLUSIONS

A method to measure the mechanical torque developed by an electrical motor is suggested.

The torque measuring method experimented by this study is the reduction case when the input is the sun gear, and we hold the ring gear stationary and attach the output shaft to the planet carrier.

Other is the overdrive case when the input is the planet carrier, and we hold the ring gear stationary and attach the output shaft to the sun gear.

We can apply our method not to the ring gear stationary case, but also to other cases sun gear stationary and planet carrier stationary.

The suggested method is very simple, very small and very inexpensive in measuring power including the torque and RPM of the motor. And this method does not need additive maintenance, because this is the non-contact method. Furthermore, on experiments, our non-contact method reduces the vibration and noise of the motor much more than we supposed to. This is caused by using elastic material and it also means that we can measure the torque more exactly and we can extend our application scope more widely.

In the case measuring torque or power is important, our solution is not only simple and cheap but also can give an instance in monitoring such values. Instant monitoring power, torque and rpm through the wireless communication are very useful and have many applications. Indeed we can make a motor unit smaller to wide our application like robot finger to control force.

In general, Planetary Gear Train is relatively more expensive than usual multistage spur gear box. But it deserves to replace usual multistage spur gear box by our Planetary Gear Train, having remote monitoring ability and more additive advantages. In conclusion, our solution has a strong point in size, cost and wireless communication. So it can give many applications on industrial field and the extension of the application is dependent on user's imagination. Moreover, the usage of piconet or scatternet of our motor units will make other applications.